Prevent More, Fix Faster: The QA Balancing Act

You’re tasked with preventing defects before they occur and also managing any issues that slip through. It’s a balancing act between being proactive to build quality into your processes and being prepared to react swiftly when something goes wrong. Quality assurance leaders in manufacturing carry a huge responsibility.

In quality management terms, Quality Assurance (QA) is inherently proactive, refining processes to prevent defects, whereas Quality Control (QC) is reactive, focused on identifying and fixing defects in finished products. Both approaches are essential. No matter how robust your QA program, mistakes can still happen due to factors outside your control, from a bad batch of materials to human error. The key is to strike the right balance: prioritize prevention to save time and cost, but also have a solid response plan for those inevitable issues.

Cost of quality rises exponentially the later a defect is caught. Fixing a problem during design may cost $1, but fixing it after products are in the field can cost $100.

Consider the classic 1-10-100 rule in quality management: catching a problem at the design or development stage might cost you $1 to fix, but catching it during production could cost $10, and finding it only after a product is delivered could balloon to $100. Studies show poor quality can eat up as much as 15–20% of sales revenue in some companies according to scilife.io. These facts underscore why a proactive approach isn’t just ideal; it’s financially imperative. At the same time, even world-class manufacturers experience the occasional recall or non-conformance.

How can you be more proactive to prevent mistakes, and what should you do reactively when problems arise? This guide will walk through practical strategies on both fronts, and show how integrating the two (with a little outside help when needed) can safeguard your operation’s quality and reputation.

Proactive Quality Assurance Checklist: Staying Ahead of Problems

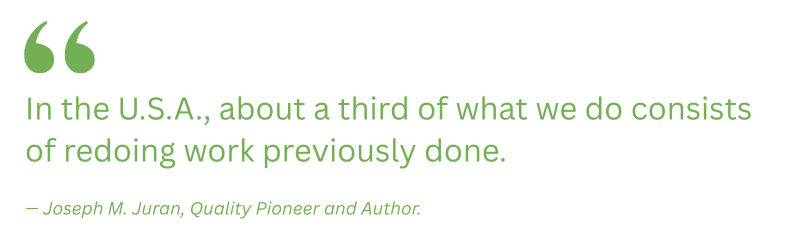

Being proactive means building quality into every step of your manufacturing process. It’s about taking measures upfront so that defects and issues never get a chance to occur. As the saying goes, “an ounce of prevention is worth a pound of cure.” In QA terms, that translates to thoughtful process design, rigorous standards, and a culture of quality consciousness.

Here are some proactive QA strategies and tools you can implement to minimize errors and enforce high standards from the start:

1. Establish a Robust QMS and SOPs

A Quality Management System (QMS) is the foundation of proactive QA. Make sure your QMS documentation (process maps, Standard Operating Procedures, work instructions) is thorough, up-to-date, and aligned with industry standards like ISO 9001. Clear, standardized procedures ensure that everyone knows the correct way to do each task, which dramatically reduces variance and mistakes.

Think of your QMS as the playbook that encodes lessons learned and best practices, so that quality isn’t left to chance. Regularly review and improve these documents as processes change or new risks are identified.

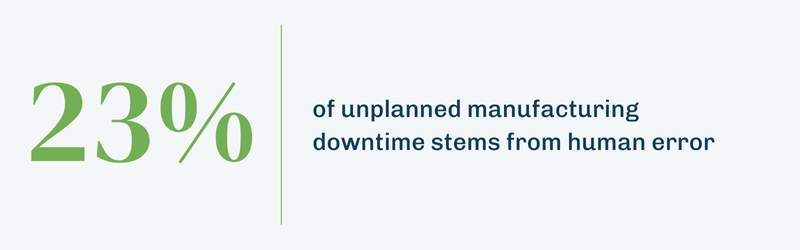

2. Invest in Training and a Quality Culture

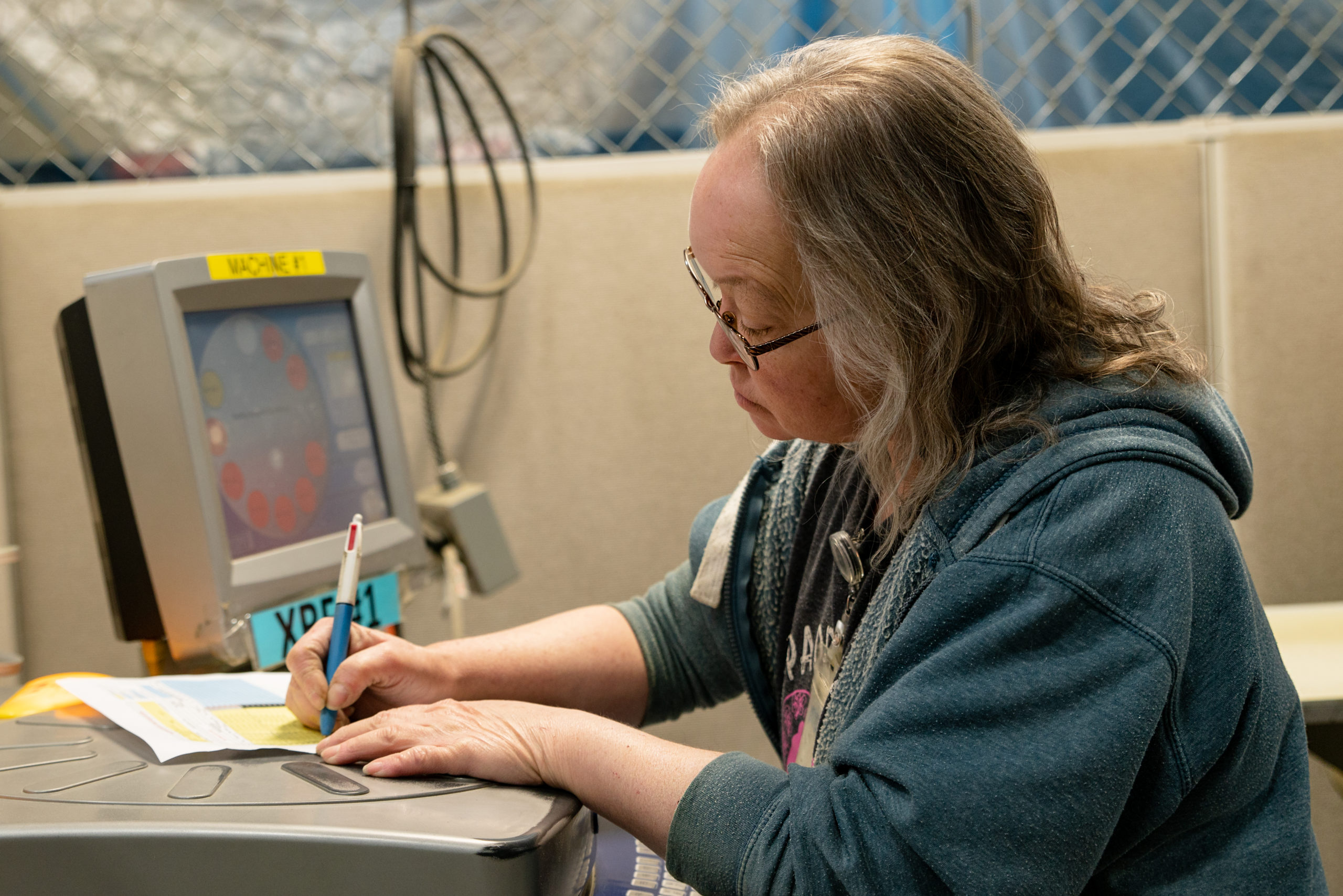

People are at the heart of quality. Proactively prevent mistakes by training employees on proper procedures, quality standards, and the “why” behind them. When operators understand the critical checkpoints and how their work impacts the final product, they are more likely to catch potential issues.

Foster a culture where quality is everyone’s responsibility by encouraging team members to speak up about irregularities and rewarding them for suggestions that improve quality. Short, focused training sessions and refreshers (especially after any process change or quality incident) keep quality top-of-mind. The goal is to make adherence to quality procedures second nature for your team.

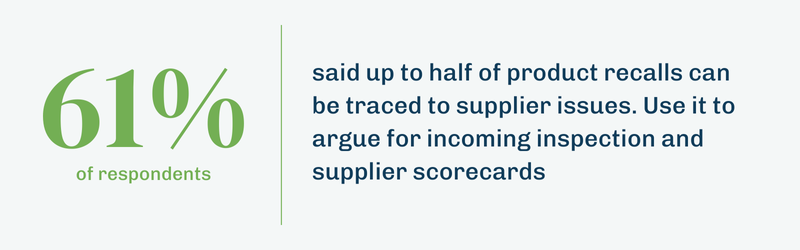

3. Rigorous Supplier Quality Management

Your output is only as good as your inputs. You should scrutinize and qualify suppliers carefully. Source materials and components from vendors who meet strict quality criteria (e.g. requiring ISO-certified suppliers or conducting supplier audits). Establish incoming inspection procedures for critical parts to catch any non-conformance before those parts enter your production line.

It can help to provide key suppliers with your quality requirements and even involve them in co-developing quality checkpoints. By front-loading quality control onto suppliers, you reduce surprises in your own operation. Evaluating vendors for rigorous standards is part of maintaining overall compliance.

4. Implement Process Controls and Automation

Mistake-proofing, automation, and in-process controls are proactive ways to ensure consistency. For example, using jigs or fixtures can prevent assembly errors, and automated sensors or vision inspection systems on the line can detect anomalies in real time. Statistical Process Control (SPC) charts might be used to monitor key quality metrics during production, alerting you to trends before they turn into defects. Automating repetitive or high-precision tasks (where feasible) also reduces human error.

While not every factory has cutting-edge Industry 4.0 tech, even simple controls including checklists, templates, or cross-check steps can significantly reduce error rates. The idea is to design your process so that it’s hard for mistakes to occur or go unnoticed.

5. Perform Regular Audits and Risk Assessments

Don’t wait for an external audit to find gaps. Conduct internal audits on schedules (and surprise spot-checks) to ensure procedures are being followed and are effective. Use tools like Failure Mode and Effects Analysis (FMEA) to proactively brainstorm what could go wrong in a process and address those potential failure modes in advance.

Assess risk at every change: when introducing a new product, changing a material, or modifying a method, do a risk review to catch possible quality impacts. This kind of vigilance can prevent “unknown surprises.” Many companies that excel in quality hold periodic cross-functional meetings to review near-misses or minor non-conformances, treating them as learning opportunities to strengthen processes before a major issue occurs.

6. Continuous Improvement and Preventive Action

Proactive QA isn’t a one-and-done effort. It’s a continuous loop of improvement. Embrace methodologies like Lean or Six Sigma to reduce variation and eliminate sources of defects. When you do catch a minor defect or deviation internally, perform a mini root cause analysis even if it didn’t escalate to a customer complaint.

Every small fix you implement proactively is potentially saving you from a bigger problem down the line. Set quality objectives (e.g. reduce internal scrap rate by X%, or improve first-pass yield by Y%) and initiate projects to achieve them. By treating quality improvement as an ongoing project, you create a resilient system that gets better year after year. Remember, preventive action (the “PA” in CAPA) is about acting on trends and weak signals before they manifest as full-blown failures.

7. Leverage Quality-Focused Partners

Part of being proactive is knowing when to get external help to maintain quality. For example, if you have a labor-intensive assembly, kitting, or packaging process that’s prone to errors or difficult to scale internally, consider outsourcing it to a specialized contract manufacturer with high quality standards. A partner like MDI (Minnesota Diversified Industries) can integrate into your process to ensure consistency and compliance from the get-go.

MDI is ISO 9001 and ISO 13485 certified and maintains strict quality control procedures, including dedicated cleanroom (white room) facilities for sensitive assembly and testing. We create detailed work instructions, parts lists, and even testing protocols to perfect the process and guarantee quality output every time. Many companies find that while making one perfect prototype is easy, replicating that perfection at scale is the hard part. A contract manufacturing partner can help by refining the process and ensuring every one of hundreds or thousands of units meets specs. By partnering with providers who share your quality ethos, you effectively extend your QA team.

MDI has spent over 50 years helping clients strengthen product quality and even minimize recalls through reliable inspection and production services. Using such a partner proactively to handle kitting of a medical device with many small components means it’s done right the first time, under controlled conditions. This kind of strategic outsourcing can mitigate risk and free your internal team to focus on core operations without worrying that quality will slip. (As a bonus, it addresses resource constraints too. MDI maintains a skilled workforce of 350+ for assembly/kitting, giving you flexible capacity with quality guaranteed.)

By taking these proactive steps, you’re essentially building a fortress of quality. You catch problems on paper or in trial runs, not in full production. You empower people and equip processes to do things right the first time. The payoff is huge: fewer defects, less rework, lower costs, and a stronger reputation. Many of the headaches that keep you up at night like surprise non-compliances or customer complaints can be dramatically reduced with prevention.

That said, no system is foolproof. Quality assurance doesn’t end at prevention; it also requires vigilance and agility when an issue does occur. In the next section, we’ll shift to the reactive side of QA: what do you do when, despite all precautions, a mistake happens?

Reactive Quality Assurance Check-List: Responding When Things Go Wrong

Even with robust preventative measures, zero defects is an aspirational goal and reality can throw curveballs. A hairline crack in a batch of molded parts, a calibration drift in an instrument, or an operator’s oversight. Issues will surface at some point. What defines a great QA leader is the ability to respond effectively and prevent a one-time slip from becoming a systemic problem or full-blown crisis. Reactive quality assurance is about damage control, root cause analysis, and rapid correction.

Here are steps and strategies for handling quality problems when they arise, ensuring you minimize impact and learn from every incident:

1. Detect and Contain the Issue Immediately

Speed is critical the moment a potential quality issue is discovered. If a defect or deviation is detected (whether on the line, in a test, or via a customer complaint), act fast to contain it. This might mean halting production on an affected line, quarantining a suspect batch of products, or pausing shipments. The goal is to prevent the problem from proliferating. Don’t let a few bad units turn into a truckload of returns.

Make sure your team knows the escalation procedure: when to call in a quality hold and whom to notify. Many companies empower any employee to call for a stop if they see a critical issue. It’s better to lose a bit of production time than to let a known defect continue down the line. Once contained, you can assess the scope: How many units are impacted? Is it isolated to one lot or more widespread? This containment buys you time to investigate without further damage.

2. Investigate with Root Cause Analysis

After containing the immediate risk, shift into detective mode. Use a structured root cause analysis approach to find out why the issue happened. Tools like the 5 Whys, Ishikawa (fishbone) diagrams, or even a formal Corrective and Preventive Action (CAPA) process can be employed here. Involve cross-functional experts if needed. Sometimes a quality issue might originate from a process setting, a machine fault, a raw material spec change, or a training gap. The key is to go beyond the superficial symptom and find the underlying cause.

For example, if a batch of parts failed a dimension check, was it due to a tool wear issue (maintenance problem), a measurement error (calibration issue), or perhaps a supplier delivering material out of spec? Peel back the layers methodically. Throughout this investigation, document everything.

Your QA records should reflect what was found and the conclusions drawn. In regulated industries, this documentation is crucial for compliance and for demonstrating control. Even in less regulated contexts, a written record helps institutionalize the knowledge so the same mistake isn’t repeated. Remember that a reactive investigation isn’t about blame, but about learning. Create an environment where team members feel safe admitting a mistake or sharing useful info (“I noticed the machine was making a strange sound yesterday”) so you can gather all the clues.

3. Implement Corrective Actions

Once you’ve identified the root cause(s), implement a corrective action to fix the problem at its source. Corrective actions are steps that eliminate the cause of the detected non-conformance so that it doesn’t continue to produce bad results. If the root cause analysis shows a machine calibration drifted, your corrective action might be to recalibrate the machine and put in place a stricter calibration schedule. If an operator missed a step because a procedure was unclear, the action could be rewriting the SOP and retraining the team. It might involve repairing or replacing faulty equipment, switching to a new material, or updating.

Make sure to verify the effectiveness of the fix: produce a few trial pieces or inspect a sample after the change to confirm that the defect is indeed gone. In many quality systems, this phase is recorded in a CAPA report where you detail the correction made. Acting decisively to correct the issue not only stops further defective output but also demonstrates to stakeholders (management, customers, auditors) that you’re in control of the situation.

4. Take Preventive Measures to Avoid Recurrence

A crucial part of reactive QA is preventive action for the future. Once the immediate issue is corrected, ask yourself: what will stop this from happening again elsewhere or in the future? This is the “PA” side of CAPA. It often overlaps with the corrective step but goes further to address system-wide improvements. For example, if a batch failed because a new raw material wasn’t tested, a preventive measure might be instituting a policy to always test new lots from that supplier, or adding that supplier to an “approved” list with tightened specs. If human error was involved, preventive action could be adding an automatic sensor check as backup, or enhancing training for all operators, not just the one involved.

You might update your risk assessments or FMEA with the new knowledge of this failure mode, and then strengthen controls accordingly. Essentially, treat the incident as a lesson to update procedures, checklists, and training materials so that everyone learns.

Many companies hold a brief post-mortem meeting after a major quality issue is resolved, to discuss what was learned and how to improve going forward. By systematically implementing preventive actions, you convert a reactive event into proactive improvements, feeding the knowledge back into your quality system for continuous improvement.

5. Communicate and Manage External Impact

If the quality slip has affected customers or could pose compliance issues, managing the external fallout is a critical reactive step. This includes communication with stakeholders such as customers, regulatory bodies (if it’s a reportable issue), and internal leadership. As uncomfortable as it is, transparency and swift communication can save your company’s reputation. If a defective products have already been delivered, you may need to initiate a product recall or field correction. Have a recall plan ready in advance (proactively) so that when you need it, you can execute quickly: identify all affected lot numbers, notify customers or distributors with clear instructions, and provide support for returning or replacing the product. Draft customer-facing communications that are honest about the issue and explain what you are doing to fix it.

While no one likes to broadcast a mistake, businesses often earn respect by handling recalls or defects responsibly and safely. If you can demonstrate that you caught the issue and are resolving it diligently, customers are more likely to be understanding. On the flip side, going silent or being perceived as covering up tends to erode trust. Part of reactive QA is public relations and compliance management. Work closely with your regulatory affairs or customer service teams to ensure all necessary notifications and documentation are completed. Inform your production and sales teams internally so they are prepared to answer questions. A well-managed reaction can actually enhance your credibility by showing that your quality system, while not infallible, is effective at issue resolution.

6. Leverage External Support for Rework and Recovery

Sometimes the scope of a quality issue can exceed your in-house capacity to address quickly. Perhaps you have thousands of units in the field that need inspection, or a large volume of product to rework or re-pack in a short timeframe. In these cases, an external partner can be a lifesaver in the reactive stage.

For example, MDI offers Product Rework, Refurbishment & Repacking services where we inspect, sort, and assemble products for resale to help manufacturers salvage unsold or non-conforming products and recoup value. If you face a recall or have stock returned due to a quality issue, you can engage a partner like MDI to perform a thorough inspection and rework of those items. Our skilled team can quickly augment your own, applying strict inspection criteria to weed out defects and then repack or refurbish items so they’re again sellable. This not only frees your hands to focus on production and corrective actions, but also ensures that the recovery work is done with high quality.

MDI’s inspection and testing services are designed to reduce recalls and protect brand reputation for their clients. We can act as a third-party checkpoint to confirm that any fixed or remanufactured products now meet compliance standards before returning to the market. Such services are especially useful in high-liability industries where you might need an extra layer of assurance that everything is 100% before re-release.

By tapping an external partner in reactive scenarios, you effectively create a safety net where you don’t have to scramble with your internal staff alone. A partner like MDI, which operates under the same rigorous quality standards you do, can be trusted to help triage and resolve quality problems swiftly. We bring capacity, expertise, and an objective eye, which together can significantly shorten the time it takes to recover from a quality setback. The end result is faster turnaround in getting your operations back to normal and customers taken care of.

Learn the benefits of outsourcing packaging

7. Document, Learn, and Loop Back

After the dust settles, take time to formally document the entire incident, from detection to final preventive measures. This documentation isn’t just bureaucracy, it’s a goldmine for learning. Include what went wrong, how it was fixed, and how it will be prevented going forward. Then close the loop by integrating those learnings into your proactive strategies. Perhaps you update your training curriculum, or you add a new checkpoint in your QMS, or you decide to increase the frequency of a certain inspection.

This is where reactive and proactive truly connect: every reactive event should spur proactive improvements. When done right, each issue you tackle makes your overall system stronger. Over time, you’ll find the issues that do occur are less severe, less frequent, and more quickly resolved, because your team and processes are continually evolving to a higher level of maturity.

By following these reactive steps, you ensure that a quality hiccup doesn’t turn into a disaster. You limit the immediate damage, find and fix the cause, handle any external obligations with integrity, and then learn from it. If proactive QA is about building a strong offense, reactive QA is your defensive game plan, and a good team needs both to win.

Blending Proactive and Reactive Approaches for Continuous Improvement

World-class quality organizations integrate both approaches into a holistic quality management system. You, as a quality leader, design robust processes and preventive measures to avoid problems (proactive), and you have rigorous protocols to swiftly deal with issues that still arise (reactive). When these two aspects work in harmony, the results are powerful: fewer defects, lower costs of poor quality, and a culture of continuous improvement.

Successful QA teams often find that their effective reactive responses feed into their proactive improvements, creating a virtuous cycle of learning. Over time, this can shift the balance more and more toward prevention, the ultimate goal.

It’s also worth noting that you don’t have to go it alone. One big challenge is balancing thorough quality oversight with operational efficiency, especially under tight budgets or limited headcount. This is where choosing the right partners and vendors becomes part of your quality strategy. Working with an external provider that upholds the same quality standards can extend your capabilities on both the proactive and reactive fronts.

When you partner with a company like MDI, you effectively gain a quality-focused extension of your team. MDI maintains rigorous quality control aligned with industry standards to guarantee product excellence, and even positions itself as a “labor supply partner who shares in the production risk and quality guarantee”. That means when MDI handles an assembly or inspection project for you, we are jointly accountable for meeting your quality requirements to relieve pressure off your shoulders without compromising on compliance or precision.

This kind of collaboration can be woven into your proactive strategy (to prevent issues via high-quality outsourcing) as well as your reactive strategy (to recover from issues via expert rework and inspection).